In the Nieuport Build Part 3 post the port wing was shown pinned down and parts glued together but at that stage the starboard wing was only temporarily pinned in position.

The starboard leading edge has since been unpinned and 3 plastic packers placed between the 2 balsa root ribs. These packers temporarily replace the 2 plywood facing root ribs that will be glued to the face of each balsa root rib at a later stage.

The starboard leading edge has since been unpinned and 3 plastic packers placed between the 2 balsa root ribs. These packers temporarily replace the 2 plywood facing root ribs that will be glued to the face of each balsa root rib at a later stage.

The picture below shows rib-lets that have now been added to the port wing. The rib-lets over each wing joining tube will be fitted after the tubes have been glued in place.

This picture shows the 3 plastic packers in place.

Note the 2 gussets from the centre section blocks to the trailing edge

have notches cut in them to allow for the aileron bell-crank boxes to fit correctly.

Note the 2 gussets from the centre section blocks to the trailing edge

have notches cut in them to allow for the aileron bell-crank boxes to fit correctly.

These packers allow the spars, balsa root ribs and leading edges to be pushed up nice and tight against each other whilst the glue is setting. The glue does not sick to the plastic packers so the 2 wing panels will separate nicely when the construction is complete. The sections are best made together to insure the wing dowels and aluminium tubes line up correctly, note at this stage the aluminium tubes have not been glued in place.

The centre section blocks have also been glued in place after minimal sanding they dropped into position, nice cutting 'boddo', spot on with the plan. The 2 gussets have also been pre-glued then glued in place, note the direction of the grain when making gussets.

Workshop Tip No. 1

The centre section blocks have also been glued in place after minimal sanding they dropped into position, nice cutting 'boddo', spot on with the plan. The 2 gussets have also been pre-glued then glued in place, note the direction of the grain when making gussets.

Correct direction for grain when making gussets.

Workshop Tip No. 1

Remember to pre-glue all end grain joints, this prevents making a 'dry' joint. If you don't when dry the joint appears glued together but if it is subjected to a sudden knock the joint more often then not breaks away from the glued area. This is due to the applied glue being drawn into the end grain of the wood and leaving very little glue on the surface to make a secure bond, pre-gluing means to apply the glue and work it into the end-grain and wait for it to dry. Once dry sand off any grain that has lifted and glue in place as normal.

Centre section front - closeup

centre section rear - closeup

Starboard wing panel with parts glued in place.

Here we see the starboard wing panel finished to the same stage as the port wing panel, however, the panels are not yet complete and still require their wingtips fitting and ailerons making. You can also see from the picture a black tube running through the wing ribs, this was a test fit of the carbon fibre aileron torque tube (the actual tube will be a little longer than that shown). All holes aligned well and the tube moved freely. It is not crucial that the tube is a tight fit in the holes of the balsa wing ribs as the main bearing point for the torque tube is in the plywood wing rib that the aileron bell-crank box is fixed against and the 3 hinge packers glued to the webbing of the aileron cut-out in the wing.

Both wing panels finished to a stage were they can be removed

from the workbench, sanded to shape and other

parts glued in place to complete the wing at a later stage.

I have been looking for the pictures I thought I had taken with regards to the construction of the ailerons and wingtips but alas it would appear that I have none!! Just pictures of the finished items but I do have pictures showing the tips and aileron prior to trimming and sanding to shape.

The ailerons are very straightforward and only have a few parts to them. Again, I made sure that all the ribs were pre-fit to the tailing edges and that the ribs were numbered so as they could be easily identified when needed as the aileron gets wider towards the tip.

The aileron leading edge was different to that supplied with the kit and mine was cut from 13mm thick sheet balsa with a rebate cut in the front edge. The rebate was deep enough to allow about 2mm of the tube to protrude from the front face.

Carbon fibre tube and rebated section off-cut.

This protrusion and spruce hinge packer that the tube is fixed against with the 'U' shaped wire retainers will give the required gap to the leading edge of the aileron when installed. So this gap was achieved whilst building the aileron by using plastic packers along with the carbon fibre tube inserted through the holes in the balsa wing ribs, ply wing ribs in the centre section and into the aileron rebate and pinned in place. The gap to the inboard end of each aileron was also achieved with a plastic packer.

The finished aileron and wing panel removed from the plan.

The aileron and wing panel still requires planing and sanding to shape.

Before I removed the wing panels and ailerons from the workbench the wing tips were added. The wing tips were made from hard 25mm wide x 4mm thick balsa sheet. The curve was achieved by holding the wood fast in one hand and gripping firmly between thumb and four finger with the other hand. Then move the thumb and four finger from the hand holding the wood fast towards the free end whilst moving though an upward curve. Keep doing this until the desired curve is obtained.

There is sufficient information on the drawing to determine the height of each tip packer that is fixed to each spar extension and supports the tip top and bottom and holds the curve in place. The packers were glued in pace to the bottom spars first then the pre-curved tips were cut to length and 'dry fitted' whilst the top packers were cut to size and 'dry fitted'.

As my wings occupied most of the workbench it wasn't possible to view the tip running its full length as the tip was almost touching the wall at one end of the bench. I overcame this problem by pacing a mirror behind the tip to see the 'flow' of the curve. Once the correct 'flow' was obtained the parts were glue in place.

This is what the tip looked like after the panel was removed from the bench.

You can see the packers between the spars and the rebated section of the aileron before the balsa filler piece was glued into the end of the aileron. You can also see how the tip terminates at the leading and tailing edges.

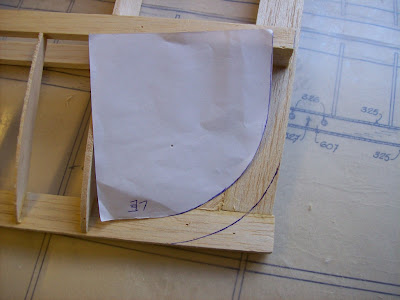

The wing tip leading edge curve was drawn onto the balsa using a simple

paper template then trimmed to size and sanded to the correct contour.

All the spar tip extension tapers were drawn onto the

wood then carefully cut out with a 'pull' saw

Here the leading edge curve has been cut and sanded.

A 'pull' saw is also visible along with the 'Perma-grit' sanding block. If you haven't got a 'Perma-grit' sanding block you can use rough abrasive paper glued to a wooden block and that will do the same job.

I can't praise the 'Pull' saw enough it's a fantastic bit of kit, they're not cheap but they last for ever cutting through balsa wood and the cut is less that .5 mm thick and the blades are extremely sharp.

The underside tapers cut roughly to shape.

The upper tapers were cut in the same fashion.

These tapers were then sanded flat from the last wing

rib to the top surface of the wing tip

To be continued...

.

.

No comments:

Post a Comment