I wanted to change the paxolin control horns supplied with the kit so that the shape was closer to those used on the full size plane. The aileron horns were discarded as torque tubes are now being used. That left 2 elevator horns, 1 rudder horn and the 2 torque tube aileron bell-cranks.

First I traced the elevator and rudder horns from an engineering drawing I have of the full size plane. Worked out the percentage of enlargement for each item and then printed them out on to paper via a desk top printer.

The enlargements were, as you can imagine quite rough, the original trace was at 1:48 scale and the printout was now at almost 1:3 scale. So the control horns were redrawn freehand on to tracing paper from the enlargements.

First I traced the elevator and rudder horns from an engineering drawing I have of the full size plane. Worked out the percentage of enlargement for each item and then printed them out on to paper via a desk top printer.

The enlargements were, as you can imagine quite rough, the original trace was at 1:48 scale and the printout was now at almost 1:3 scale. So the control horns were redrawn freehand on to tracing paper from the enlargements.

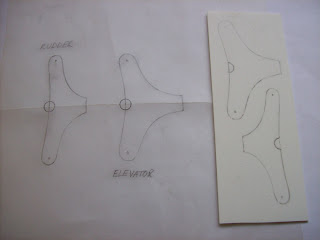

I folded a piece of tracing paper in half and drew half of the horn onto the tracing paper, using the enlargement as a guide. The fold line of the tracing paper being on the centre line of the horn. Whilst the trace was still folded in half I turned it over and transferred the horn outline onto the reverse side of the tracing paper using a pencil. When the trace was opened up it revealed the complete control horn outline. I also marked on each horn tracing the position for the carbon fibre tube.

Horn traces and HIPS marked up prior to trimming out.

You can also see from the above picture that I have transferred the traced image to a piece of white HIPS (High Impact Polystyrene Sheet), also known as plastic card. The beauty of this material is that you only have to score the surface with a sharp knife then crack it to separate the wanted part from the waste.

After the plastic card templates had been cut out, cleaned up and pilot holes drilled I used the templates to scribe the shape onto the paxolin sheet. The paxolin sheet was first sanded down then the component shapes scribed on to the surface using a sharp implement.

Elevator and rudder template horns cut out and pilot holes drilled.

Horns scribed onto the paxolin sheet ready fro cutting out.

After the shapes had been scribed onto the paxolin sheet, the sheet was given a wipe over with a tissue. The dust left on the surface from sanding fills in the scribed lines and makes them more visible and easier to follow when cutting them out with a fretsaw.

Here you can see the 3 finished horns cut out and

cleaned up and with pilot holes drilled.

You can see in this picture the difference between the

revised horns and the horns supplied with the kit.

Next came the aileron bell-cranks, these I drew to suit my aileron torque tube system. They will look similar to the full size plane.

Rough sketch showing aileron torque tube bell-crank and spar detail.

The above picture shows a sketch of the aileron bell-crank and how it fits around the scale rear spar detail. The cut out in the bell-crank shown in the sketch is to allow the bell-crank to rotate around the scale spar.

After taking measurements from the wing centre section, position of scale spar and the 'travel' of the horn a trace was produced.

An aileron bell-crank trace was drawn up and from it a template cut from plastic card. The bell-crank outline was then scribed onto the surface of the paxolin sheet using the plastic card template as a guide. After the bell-crank shapes were scribed onto the surface of the paxolin they were wiped over with a tissue to fill the scribed lines with dust making the line more visible The apertures were then cut and pilot holes drilled and finally the bell-cranks were cut out using a fretsaw.

Bell-crank trace and bell-crank drawn onto

plastic card prior to trimming out.

Bell-crank template trimmed out and pilot hole drilled.

Bell-crank scribed onto paxolin sheet ready for

cutting out with a fretsaw.

When fretsawing, if the items you are cutting out have small fiddly holes or shapes cut into them (like these bell-cranks) make sure you cut these apertures out first.

It is far easier and safer to cut these apertures out when the item is still attached to the sheet. Your task will be made that much harder trying to drill and cut out the apertures after the main item has been removed from the sheet.

It is far easier and safer to cut these apertures out when the item is still attached to the sheet. Your task will be made that much harder trying to drill and cut out the apertures after the main item has been removed from the sheet.

Bell-cranks cut out, pilot holes drilled and cleaned up.

The aileron horns were cut from paxolin sheet, all apertures were cut out first.

Having made the paxolin horns and bell-cranks I moved on to the rigging plates. These plates were made from stock mild steel strip as supplied in the kit. All the holes require marking out and drilling then filing to shape.

It's a good idea to mark up and drill pilot holes in just one bracket. This bracket can then used as a drilling template for all the others, saving time and keeping the holes consistent without measuring each bracket individually. After you have drilled the pilot holes these can then be opened up to the correct size and the brackets cleaned up and corners rounded off.

Finished rigging brackets and fixings.

The next blog will show the control horns being fitted into the rudder and elevators and the bell-cranks being fitted onto the aileron torque tubes.

Workshop Tip No. 6

When fretsawing, if the items you are cutting out have small fiddly holes or shapes cut into them make sure you cut these apertures out first.

It is far easier and safer to cut these apertures out when the item is still attached to the sheet. Your task will be made that much harder trying to drill and cut out the apertures after the main item has been removed from the sheet.

It is far easier and safer to cut these apertures out when the item is still attached to the sheet. Your task will be made that much harder trying to drill and cut out the apertures after the main item has been removed from the sheet.

The apertures in these bell-cranks were all cut out before

the main component was cut from the sheet material.

the main component was cut from the sheet material.

You should also use a fretsaw cutting table when cutting out components. This will help support either side of the cut and help prevent the component or blade from breaking.

Simple fretsaw cutting table made from MDF, a clamp and fretsaw.

To be continued...

Hi Mark.

ReplyDeleteExcellent workmanship,congratulations!

Just can't wait to see the horns and bellcranks installed.This is very interesting and informative indeed!

Regards,

Socrates

Hi Socrates,

ReplyDeleteMany thanks for your kind words, very much appreciated.

I'm glad you are finding each post of interest and look forward to reading each installment. The horns and bell-cranks are now installed, check out the next update...

Regards, Mark