The completed tapers on the 2 aileron bell-crank boxes.

The boxes now have to be fitted into each wing panel. The full size Nieuport had a visible rear wing spar that ran through the aileron bell-crank. The "Boddo's" Nieuport has 2 rear spars and for the addition of the more scale like aileron bell-cranks this would have to be reduced to 1 rear spar.

The existing rear spars in each wing panel were cut short during construction as previously mentioned to allow for the insertion of the aileron boxes. Then the balsa root ribs and inboard plywood ribs had apertures made between the top and bottom balsa spars to allow for the 'scale' spruce spars to slide in between the spars that were cut short. The spars that were cut short will eventually be glued to the aileron bell-crank boxes and the single rear spruce spars thus giving that area the required strength and rigidity.

The existing rear spars in each wing panel were cut short during construction as previously mentioned to allow for the insertion of the aileron boxes. Then the balsa root ribs and inboard plywood ribs had apertures made between the top and bottom balsa spars to allow for the 'scale' spruce spars to slide in between the spars that were cut short. The spars that were cut short will eventually be glued to the aileron bell-crank boxes and the single rear spruce spars thus giving that area the required strength and rigidity.

Port aileron box detail showing aileron torque tube

and single spruce rear spar. 'dry-fitting'

and single spruce rear spar. 'dry-fitting'

Plan view of port aileron box detail showing aileron torque

tube and single spruce rear spar. 'dry-fitting'

tube and single spruce rear spar. 'dry-fitting'

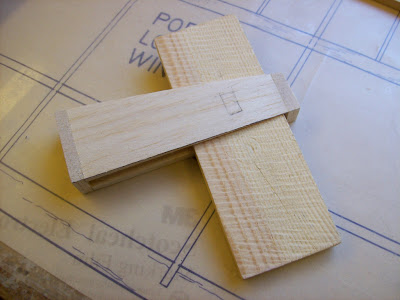

This shows the port wing component parts, torque tube,

spruce spar and aileron bell-crank box.

spruce spar and aileron bell-crank box.

Fist I had to cut the apertures in each wing panel between the rear balsa spars for the single spruce spar to fit through. Cutting the opening in the balsa root rib presented no great problem this cannot, however, be said for the inboard ply rib. I managed to drill a hole through the plywood rib then had to open it up using a scalpel knife whilst bending the 2 balsa rear spars to one side.

Port wing panel showing opening cut into balsa root rib and the starboard

wing panel marked out ready for the opening to be made.

The reason why these openings were left until now was to keep the wings aligned during the construction stage. The wings were quite fragile after being built around the area of the centre section curved blocks and trailing edge gussets. This will be alleviated when the spruce spars and aileron bell-crank boxes are fitted.

The starboard wing 'weak spot' is shown here. The only part holding

the tailing edge of the wing together from the centre section

block is the triangular balsa gusset.

the tailing edge of the wing together from the centre section

block is the triangular balsa gusset.

A good job we 'pre glued' those gusset joints!

Closeup showing the starboard wing apertures for the single spruce rear spar.

It would have made the construction more difficult had these

apertures been cut before the build started.

apertures been cut before the build started.

Here the starboard wing spruce spar is 'dry fitted' to ensure a good fit.

It still requires trimming to the correct length.

Now we have the spar in place we can start work fitting the aileron box. Remove the spar and 'dry-fit' the aileron box into place, slide the spar in until it touches the aileron box then mark its position with a pencil line, remove spar and box.

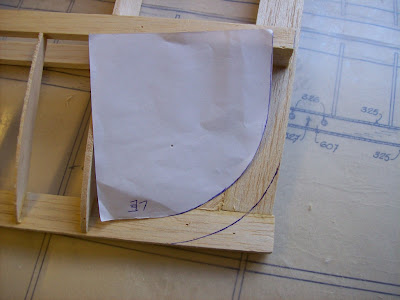

Aileron box with spar position marked on and ready for cutting out.

A wooden block was paced inside the box to cut against, remember the box has been sanded to a taper and is very fragile at this stage. I reinforced the tapered joint with thin cyanoacrylate to help keep it in one piece.

Aileron box with spar opening cut out.

Place the aileron box back in to the starboard wing and slide the spruce spar in again and mark the second position of the spar onto the box then remove components and cut out the hole as before, using the block inside the box to cut against.

Spruce spar fitted through aileron box.

Aileron box and spar 'dry-fitted', now onto the next stage,

fitting the aileron torque tube.

With the aileron boxes in place I sanded the end of the carbon fibre torque tube and slid it through the holes in each wing rib until it reached the aileron box. The tube was then rotated and the carbon dust on the end of the sanded tube was sufficient to mark the position on the box for cutting out the first hole.

Carbon tube in place, rotated to mark the position

of the tube for cutting out the first hole

of the tube for cutting out the first hole

Position of tube marked in place.

Cut out the first hole as before with wooden block inside to cut against, place the aileron box back in the wing and mark the second hole in the same way, remove and cut out the hole.

The aileron box is now finished and ready for gluing in to position.

Wooden 'packers' were put between the two rear spares and inside

the aileron box to keep all the joints tight whilst the glue was setting.

After gluing the boxes in place I moved on to the aileron cut-outs and filled in the gaps between the ribs with balsa wood strip, behind the webbing that the ailerons will be secured to at a later stage.

Before fitting the balsa strip.

After fitting balsa strip.

The top wings can now be put to one side to dry. In the next part I will be making the lower wings.

To be continued...

.

.