The first items I sanded down were the 2 aileron boxes. These would need sanding flush with the wing ribs top and bottom. The possible problem here is whilst you are happily sanding down the 'high spot', in this case the aileron boxes, you will inevitably sand down the wing ribs on either side, bad.

So it is a good idea to apply some masking tape to the top and bottom of each rib either side of the aileron boxes. The tape will prevent the sanding block from removing material from the ribs but will allow the material in the middle to be sanded down to the required amount. If you sand through the masking tape, at that point stop sanding and remove the old masking tape and reapply a fresh piece. When you are happy with the result remove the masking tape.

Here you see the masking tape in position prior to sanding.

The sanding block being drawn over the aileron box. The ribs

either side are protected with masking tape and will

remain untouched and their shape retained.

The same procedure was adopted for the top wing centre section.

The top wing components were then marked up ready for planing and sanding in the same way as the tailplane.

A ball point pen was used for drawing the lines to the leading and trailing edges of the wings. The ailerons were also marked up, leading and trailing edges.

Port wing leading edge marked up.

Trailing edge centre section marked up.

The angled line shown on the end grain of the centre section trailing edge in the above picture was derived at by extending a visual line from the top of the wing rib. When this is planed and sanded down it will follow the line of the wing rib. Because some of the wing ribs have a blunt end It may be necessary to extend the end of each rib that forms the aileron cut-out so a smooth section is achieved when covered. The other wing ribs that are glued to the tailing edge will not require extending and can be left as they are and will not show when covered.

Trailing edge marked up at aileron cut-out section.

When this is sanded down the rib should blend smoothly

into the trailing edge so as to achieve a good finish when covered.

Aileron webbing cut-out marked up.

Aileron leading edge marked up, rear.

Aileron leading edge marked up, front.

Also visible is the rebate for carbon fibre torque tube.

Next the surplus wood was fist planed off then sanded with a rough sanding block and then finished with a fine sanding block.

Wood being planed away from the wing aileron webbing and spar.

This was done slowly and carefully so as not to damage any of the wing ribs.

All the trailing edges were then planed down,

again taking care not to damage the wing ribs.

A sanding block was then used to blend the ribs in with the trailing edge.

The trailing edge was rounded off later during the final stages.

The top wing ribs were then sanded along with the front

edge of the leading edge to obtain the correct profile.

The lower section of the leading edge was

also planed and sanded to achieve the above profile.

Problem area around the centre section.

During the sanding process I could see a problem area around the centre section. As can be seen from the above picture. The fabric would have struggled to blend nicely from the centre section block to the trailing edge. The answer was to add a further block of balsa and sand it to shape. This would act a 'land' for the fabric to fix to and to hold the shape along the curved cut-out of the centre section.

Additional balsa block glued in place.

Balsa block after sanding, still requires a small amount of filler to finish.

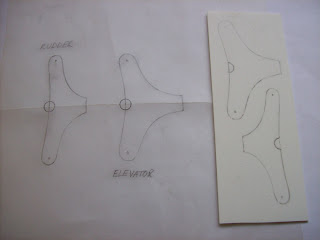

Using the finished panel as a template to mark up the next panel.

Each aileron tip section of the rebate needed filling in with balsa wood, the carbon fibre torque tube would then butt up against this block when finished. This infill is required so as to obtain the top and bottom aileron tip taper.

Aileron tip before fitting balsa infill.

Aileron tip after fitting the balsa infill, this was sanded flush when dry.

Planing down the the aileron leading edge.

The aileron leading edge was then planed down, taking care not to damage any wing ribs. The leading and trailing edges were then sanded down using masking tape to prevent sanding down the aileron ribs.

Tape applied to the ailerons to prevent sanding down the ribs.

Aileron tip tapers and trailing edge marked up ready to be sanded to shape.

Sanding the wing tip taper, underside of starboard wing.

When I had finished sanding down both of the wingtip tapered supports top and bottom I moved on to the wingtips.

Wingtips are always a bit of an anomaly and the drawings can only show you so much. Wingtip sections are always welcome and the more you have on a drawing then all the better. So interpret the drawings as best you can, decide your plan of attack and stick to it. It helps if you can work the 2 together, this will help keep them looking the same during construction.

With this Nieuport kit the wingtips to the bottom wings are the easiest type to make as you can see from my earlier post but the top wing is a little trickier. So I hope you will find the following pictures showing my interpretation of the wingtips useful. But remember it's only my interpretation of what I deem right. Just try and achieve a nice flowing curve from leading edge to trailing edge and that will be fine.

The before picture, as you can see it looks a little odd at this stage.

And.. the after picture, now we just need to get the starboard tip to match!

Closeup on wingtip, front section.

Closeup of wingtip, aileron section.

In the next post I will be planing and sanding to shape the lower wings.

To be continued...

Workshop Tip No. 4

When you need to sand down a 'high spot' it is sometimes possible to apply masking tape to either side of the 'high spot'. The masking tape will allow the sanding block to pass over the taped area but sand down the 'high spot'. If you sand through the tape before you have finished then remove the tape and apply a new piece.

This method can also be used if you are reinforcing the centre section of a polystyrene and wood veneer covered wing with either epoxy or polyester resin and glass cloth. Apply the masking tape to either side of the finished glassed area then sand it down. The tape will protect the surface, if you sand through the tape remove it and apply a new piece. The last thing you want to do is sand down the thin wood veneer as it will greatly reduce the strength of the wing around that area of the centre section. The main reason for glassing the centre section in the first place is to reinforce this high stressed area, this will be greatly impaired if you sand down the wood veneer to either side.